High viable count, high activity, high stability, high lactic acid production, rapid pH reduction, low opening temperature, high aerobic stability

This product works synergistically with a variety of lactic acid bacteria to produce a large amount of lactic acid and propionic acid substances, which can quickly reduce the pH value and inhibit the growth and secondary fermentation of harmful bacteria such as mold and clostridium. It prevents mold and corruption, and reduces dry matter loss. Under normal circumstances, the total loss during the fermentation, cellar opening, and material collection stages is about 20%. Adding this product can reduce the loss by 8-15%. Some aromatic substances produced during the lactic acid fermentation process can increase the aroma of silage and enhance the feed intake of dairy cows. The dominant beneficial bacteria can also improve the digestibility and absorption rate of dairy cows, increasing feed compensation.

Product Name: SD-705 (Silage Fermentation Agent)

Product Type: Mixed feed additive microorganism

Ingredients: Lactobacillus buchneri, Lactobacillus plantarum, Pediococcus pentosaceus, maltodextrin

Total Number of Viable Bacteria Added at Factory: ≥1.1×10¹¹ CFU/g

Product Efficacy and Features:

- Improve silage effect and ensure silage quality:

Lactic acid bacteria ferment quickly to produce rich lactic acid, formic acid, propionic acid, and other organic acids, rapidly reducing pH. - Improve the dry matter recovery rate of silage:

Lactic acid bacteria grow and reproduce quickly to produce acid, allowing silage to enter the lactic acid fermentation period as soon as possible, inhibiting the growth and reproduction of spoilage bacteria and reducing dry matter loss. - Accelerate the silage fermentation speed and quickly reduce the pH of silage:

The three types of lactic acid bacteria produce acid quickly and in large quantities, rapidly lowering the pH value and performing heterotypic fermentation, prolonging the silage shelf life and preventing secondary fermentation. - Improve the palatability of silage and increase feed intake:

Silage fermented by lactic acid bacteria is fresh, green, and has a special aroma. The fragrant and sour taste can stimulate the appetite of animals and has a good promoting effect on the growth and development of the body.

Recommended Dosage

Add 2.5-5g of starter to ferment 1 ton of whole corn.

Storage Conditions and Methods

Store in a sealed container in a dry, ventilated place away from light. The effect is better when stored at low temperature.

Shelf Life

24 Months

Net Content

250 gram

Precautions

- It is recommended to use it once after opening to avoid getting damp and affecting the use effect.

- Stir and dissolve this product in water before use to prevent precipitation from forming and causing uneven spraying.

Product Usage Process

- Dissolve 250g of Silage Fermentation Agent in a 15L bucket. Stir until there are no lumps.

- Add it to a 300L bucket and spray evenly on the green leaves.

- The spraying time is about 1.5h-2h, and each barrel of silage. The starter solution can be used to spray 50-100 tons of silage.

- Sealing the cellar: Gradually seal the cellar from the inside to the outside, with the first layer of transparent plastic sheeting, the second layer of black and white film, and tire pressing.

The Three Stages of

Silage Fermentation

The First Stage

(Early Stage of Fermentation)

Environment:

Aerobic environment

Process:

Aerobic bacteria: Sugar → CO₂ + H₂O + heat

Results:

-

-

-

- Energy loss

- Sugar reduction

- Increased fiber ratio

-

-

The Second Stage

(Mid Fermentation)

Environment:

Anaerobic environment

Process:

Aerobic bacteria: Sugar or lactic acid produces acid pH

Results:

-

-

-

- Protein Degradation

- Increased starch digestibility

- Silage agent can shorten fermentation time

-

-

The Third Phase

(From the Opening of the Cellar to the Completion of Feeding in the Entire Cellar)

Environment:

Aerobic environment

Process:

Aerobic bacteria: Sugar or lactic acid → CO₂ + H₂O + calories

Results:

-

-

-

- 50% aerobic loss occurs at this stage

- Silage additives reduce losses

-

-

Basic Experimental Data

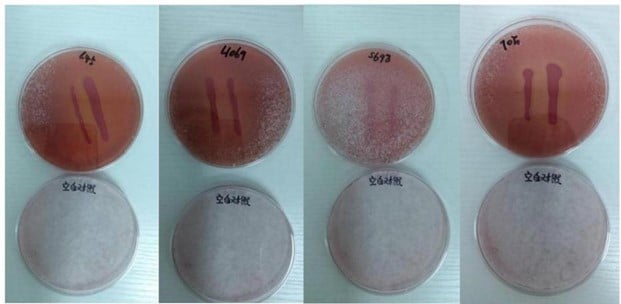

Studies have shown that Pediococcus pentosaceus, Lactobacillus plantarum,Lactobacillus bucheri and the finished SD-705 complex strain are all effective against mold inhibitory effect, the effect will be better after reasonable combination.

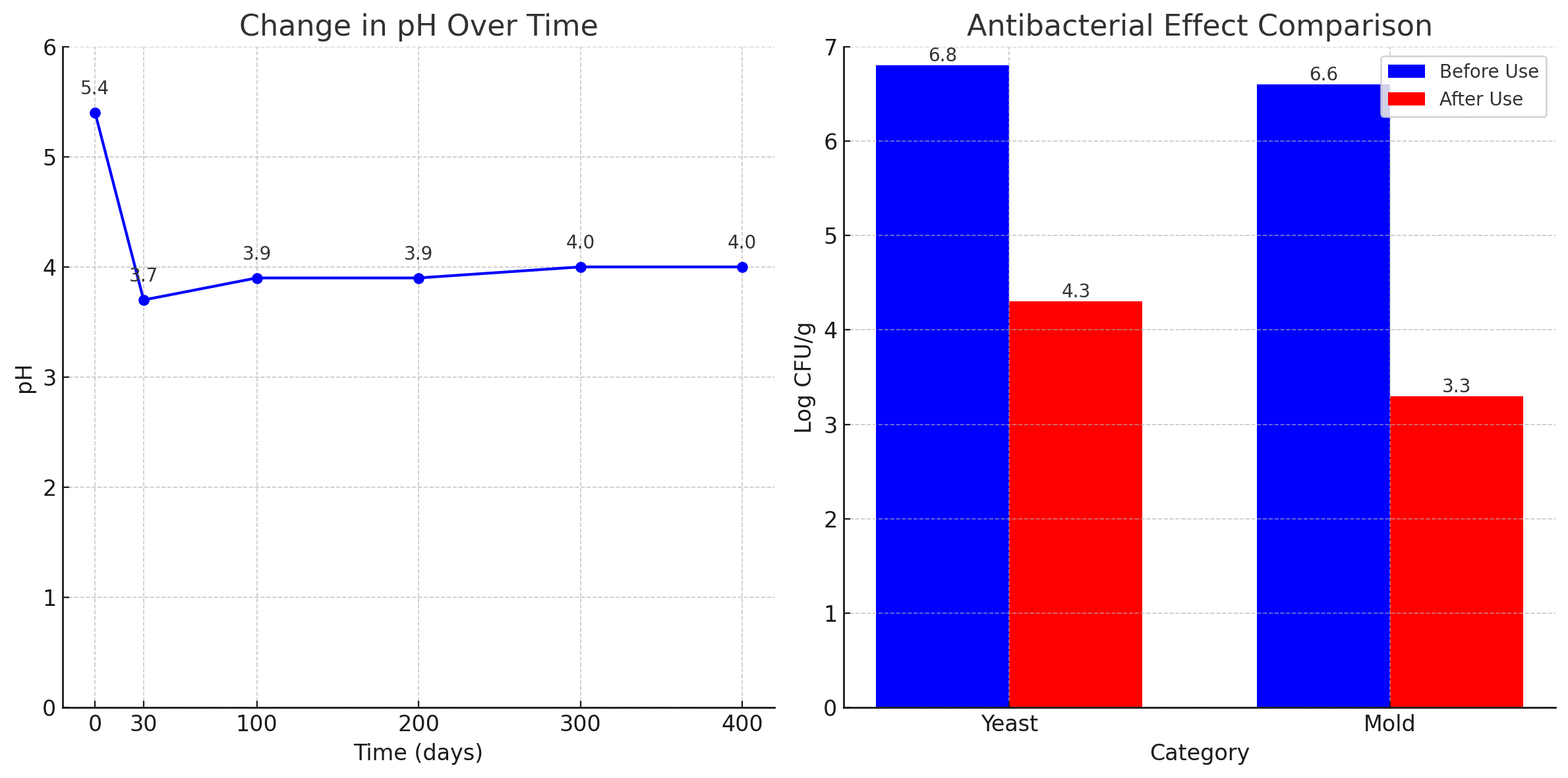

Changes in pH, yeast and mold during silage fermentation

Corn silage fermented with SD-705, pH The value of lactic acid bacteria decreased rapidly from 5.4 to 3.7 within 30 days , indicating that the fermentation speed of lactic acid bacteria was fast, producing abundant lactic acid, formic acid, propionic acid and other organic acids, achieving rapid reduction of pH The purpose of yeast and mold activity The bacterial count was reduced by 37% and 50% respectively after using this product. Its mechanism of action is that lactic acid bacteria grow rapidly and reproduce.Acid can make the silage enter the lactic acid fermentation period as soon as possible, inhibit the growth and reproduction of spoilage bacteria, and reduce dry matter loss.

Test Report

| No. | Inspection Item | Unit | Inspection Result | Limit Requirement | Standard | Inspection Method |

|---|---|---|---|---|---|---|

| 1 | Odor | / | Odorless | Odorless, no abnormal smell or peculiar smell | Compliant | Q/Q1YSW 02-2024 |

| 2 | Color | / | Product inherent color | Product inherent color, no obvious difference | Compliant | Q/Q1YSW 02-2024 |

| 3 | Form | / | Powder | Powder or fine granular form | Compliant | Q/Q1YSW 02-2024 |

| 4 | Granularity | % | Product 100.0% passes through 2.0 mm sieve. Standard deviation of samples passing through 1.0 mm sieve is not less than 10%. | 100.0% passes through 2.0 mm sieve. Standard deviation of samples passing through 1.0 mm sieve is not less than 10%. | Compliant | GB/T 5917.1-2008 |

| 5 | Moisture | % | ≤10 | ≤10 | Compliant | GB/T 6435-2014 |

| 6 | Lead (Pb) | mg/kg | Not detected (<0.1) | ≤5 | Compliant | GB 5009.12-2017 |

| 7 | Arsenic (As) | mg/kg | Not detected (<0.05) | ≤2 | Compliant | GB 5009.11-2014 |

| 8 | Total Plate Count | CFU/g | <10 | <10000 | Compliant | GB 4789.2-2016 |

| 9 | Coliform Bacteria | MPN/100g | <3 | <90 | Compliant | GB 4789.3-2016 |

| 10 | Salmonella | /25g | Not detected | Not detected | Compliant | GB 4789.4-2016 |

| 11 | Mercury | mg/kg | Not detected (<0.05) | ≤0.3 | Compliant | GB 5009.17-2014 |

| 12 | Cadmium | mg/kg | Not detected (<0.003) | ≤0.5 | Compliant | GB 5009.15-2014 |

| 13 | Staphylococcus aureus | /25g | Not detected | Not detected | Compliant | NY/T 2071-2011 |

| 14 | Bacillus cereus | /25g | Not detected | Not detected | Compliant | NY/T 2071-2011 |

| 15 | Mold and Yeast | CFU/g | <10 | <100 | Compliant | GB 4789.15-2016 |

| 16 | Lactobacillus | CFU/g | 1.2×10^10 | ≥1.0×10^10 | Compliant | GB 4789.35-2016 |

Feel Free to

CONTACT US

Phone ~ WhatsApp ~ WeChat

+86 155 8868 7128

Tsingtao Jummos Agricultural Technology Co., Ltd.

sue.su@silopak.com

SILOPAK.COM I © 2022-2024 All Rights Reserved